Automatic Measurement is a main function for automated object inspection for faster, more efficient and more accurate quality control process. It is...

Automatic Measurement is a main function for automated object inspection for faster, more efficient and more accurate quality control process. It is...

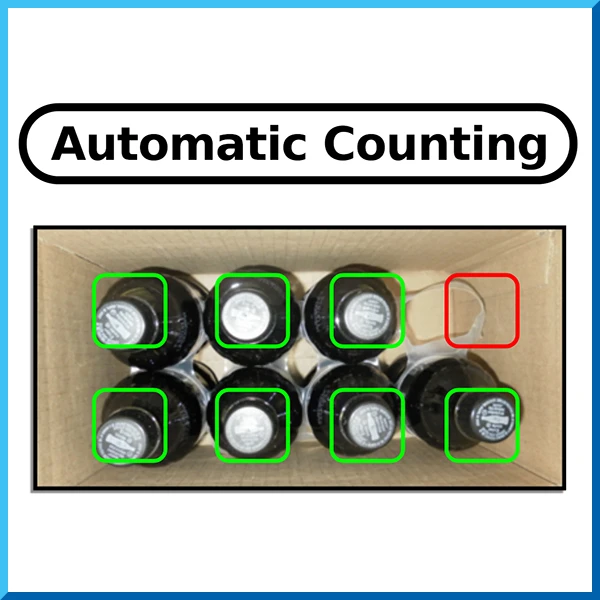

Object counting is a common task performed in different industries. It is all about figuring out how many objects are in an image. Therefore, with...

To ensure that the barcode can be read, the barcode must first be decoded. This is done via acquiring an accurate and reliable barcode image to...

The identification labels are normally made of a set of printed elements, such as product descriptions, logos, 1D/2D barcodes, ingredients, and...

A high-accuracy, high-speed, high-yield, object location machine vision. It covers a broad range of pattern matching and location inspection and...

In bottling assembly lines, it is especially important to determine whether the bottle has been filled to an acceptable level and whether the cap is correctly placed and positioned. The throughput rates can be high, and the detection of small defects is a key factor for quality control. Cap defects can cause leaks or product contamination. The machine-vision inspection has image-processing tools that allow programing the system by loading images of “good” and “bad” parts, establishing an inspection standard